Woodworking Planer Machine Four Side Moulder for Solid Wood

$9,700.00

1.Each main shaft is driven by independent electric motor,cutting force is powerful

2.Main shaft is adjusted to focus on the front,operation is convenient.

3.Hard chrome plating work table is durable.

4.Equips with auxiliary unit alarming lack of material,it effectively improves smooth feed-in while lack of material.

5.Multi-group drive rollers improve feeding efficiency.

6.Pneumatic compressed feeding roller is applied,the pressing force can be adjusted by stages which is favorable for smooth feeding of timbers with different thickness.

Greatly improve the processing capacity and production efficiency by shortening the auxiliary working time.In addition, it reduces the number of traditional machine tools, saves the number of operators and reduces the floor area of the workshop.

1. Improve processing capacity and production efficiency.

2. Improve wood yield.

3. Improve product quality and processing precision.

4. Expand the technological range and increase the product variety.

2.Each main shaft is driven by independent electric motor, ensuring powerful cutting force.

3.Multi-group drive rollers improve feeding efficiency.Alarming system starts when lack material.

4.International brands electrical parts are applied for good stability.

5.Spare parts are thick and solid to maintain high precision, reliability and stability.

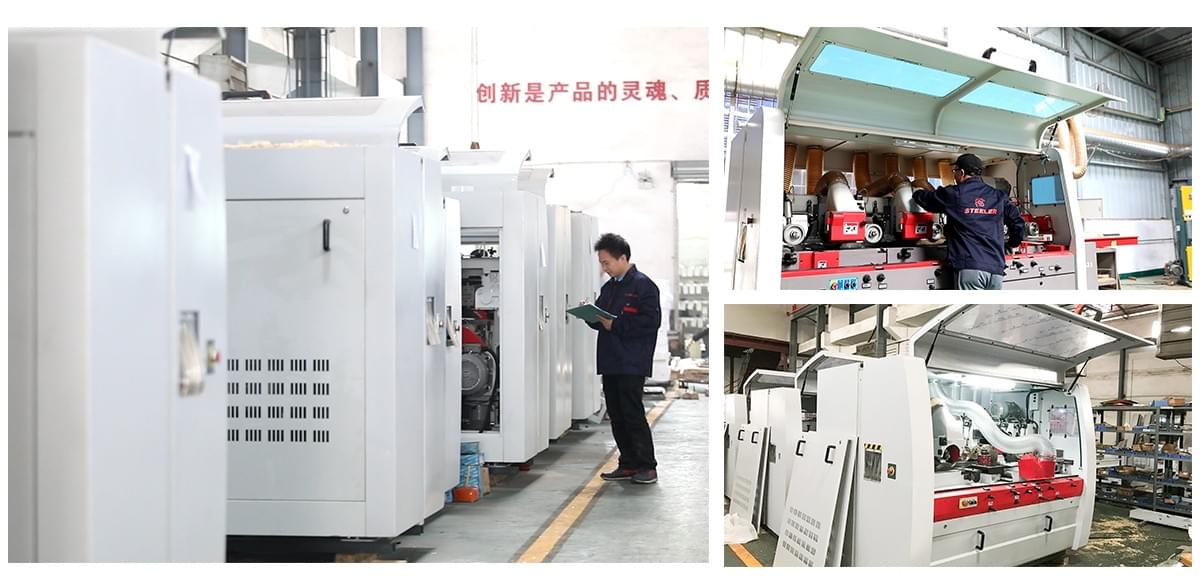

As a Factory, We can meet your custom requirements!

If you are an end customer, tell us your processing requirements and drawings, and we will recommend the most suitable machine for you;If you have plans to sell this machine, tell us your parameters and appearance customization requirements, we will meet your needs.

TEAM AND PARTNERS

Our products are exported to more than 50 countries and regions, such as

Europe, Russia, Southeast Asia, Middle East, North America, Australia,Africa.

HAVE A QUERY?

We’ve mapped out a few answers for you right away.

1. What is the processing width of this machine?

We have a range of 120mm-330mm to choose from, and can also be customized.

2.Does the machine come with cutters?

Because the processing requirements of each customer are different, the machine does not come with knife, but the tool can be customized according to the drawing.

3.What is the delivery time of the machine?

The delivery time for regular models is about 35 days.

4.Do you support customization?

We support customization of voltage, machine color, spindle power, etc.

5.How to solve after-sales and installation problems?

After the machine is debugged, the whole machine will be transported, we support on-site and online technical support

WHY CHOOSE STEELER?

we have 20 years of experience in making woodworking machines.

YOU MIGHT WANT THESE PRODUCTS